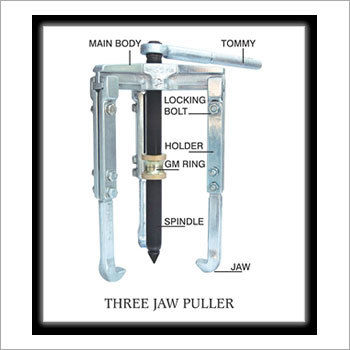

Three Jaw Pullar

Three Jaw Pullar Specification

- Color

- Silver

- Type

- Three Jaw Puller

- Material

- Forged Steel

- Power Source

- Manual

- Dimensions

- Varies (Common sizes: 4 to 12 inches)

- Weight

- Approximately 1.5 kg (varies by size)

- Thread

- Metric, high-strength thread

Three Jaw Pullar Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Delivery Point (DP), Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- Set

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Boxes,Cartons.

- Main Domestic Market

- All India

About Three Jaw Pullar

Our team of highly qualified & experienced workforce helps us in manufacturing and supplying Three Jaw Pullar. This puller is made from carbon steel with forging and special heat treatment. As the name suggests, this high quality range is suitable for removing industrial bearings and idealized for general purpose usage. Mainly, the pullar is designed to be used for removing gear or pulley in most effective manner from the center shaft that pressed the tolerance in between shaft and gear. We offer Three Jaw Pullar at pocket friendly prices to clients.

Features:

- User friendly design

- Resistant to high impact

- Resistant against corrosion

Superior Grip and Versatility

Designed with adjustable, reversible jaws and a self-centering function, the Three Jaw Puller adapts to various sizes and shapes, offering secure extraction of press-fitted components. Its reach and spread accommodate a broad range of gears and bearings, making it an indispensable tool for professionals.

Durable Construction for Longevity

Crafted from forged steel and coated for anti-corrosion, this puller provides exceptional reliability and lifespan in harsh working conditions. The heat-treated handle ensures comfortable and safe operation during repeated use, delivering consistent performance in demanding environments.

Mechanical Safety and Compliance

This tool complies with recognized safety standards for mechanical hand tools, ensuring each operation is stable and secure. Its manual operation with metric high-strength threads prevents slippage and accidents, making it ideal for mechanical, automotive, and industrial applications.

FAQs of Three Jaw Pullar:

Q: How do I use the Three Jaw Puller for removing gears or bearings?

A: To operate the Three Jaw Puller, first adjust the jaws to securely grip the part to be removed. Ensure the tools center screw is aligned with the shafts axis. Tighten the handle gradually, applying even force as the self-centering jaws pull the component away from its seated position.Q: What components can be extracted using this tool?

A: The Three Jaw Puller is ideal for removing gears, bearings, pulleys, and other press-fitted parts found in mechanical, automotive, and industrial equipment. Its adjustable jaws accommodate various sizes, enhancing its versatility.Q: When should I choose a Three Jaw Puller over other types?

A: Choose a Three Jaw Puller when you require balanced, self-centering extraction for three-point contact on components. Its design minimizes damage to parts and ensures even force, particularly useful in precision mechanical and maintenance work.Q: Where can the Three Jaw Puller be effectively used?

A: This tool is highly effective in mechanical workshops, industrial facilities, and automotive service centers. Its adaptability and sturdy build make it suitable for professional environments needing reliable gear and bearing removal.Q: What is the process for adjusting jaw spread and reach?

A: Jaw spread and reach are adjusted by repositioning the arms on the pullers frame and selecting the appropriate model size. This enables efficient extraction of different sized components, with a maximum jaw spread up to 300 mm and reach up to 150 mm (varies by model).Q: What are the benefits of the polished, anti-corrosion coated finish?

A: The polished and anti-corrosion coated surface enhances durability, protects against wear, and prevents rust, ensuring the tool maintains optimal performance and a professional appearance over prolonged service life.Q: Is the Three Jaw Puller compliant with mechanical safety standards?

A: Yes, the Three Jaw Puller is manufactured to conform with established mechanical hand tool safety guidelines, providing secure manual operation and high-strength metric threads to minimize risk during use.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 3300355 Sets

- Delivery Time

- Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mounting - Dismounting Tools Category

Chiisel Jaw

Price 3500 / Set

Minimum Order Quantity : 1 Set

Thread : M14

Color : Yellow and Black

Power Source : Corded Electric

Induction Heater

Price Range 86000.00 - 400000.00 INR / Set

Minimum Order Quantity : 1 Unit

Thread : M8

Color : Grey

Power Source : Electric

Two Jaw Pullar

Price Range 5000.00 - 32000.00 INR / Set

Minimum Order Quantity : 1 Set

Thread : Precision Machine Cut

Color : Silver

Power Source : Manual

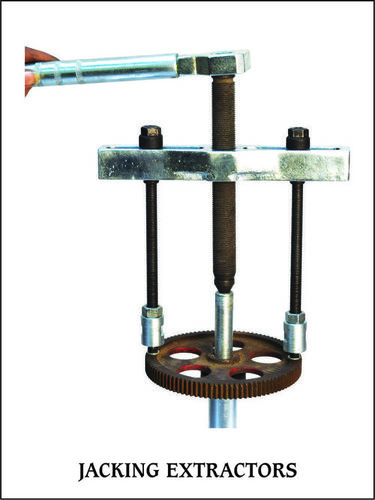

Jacking Extrators, Bearing Puller Attachment

Price Range 11000.00 - 35000.00 INR / Set

Minimum Order Quantity : 1 Set

Thread : Standard Metric

Color : Silver

Power Source : Manual

|

EKTA ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |